Let the testing begin…

Yes, this is indeed the summer of testing and discovery for me. Since the start of my “soft” retirement two years ago, I’ve been backing out of my regular day jobs that I don’t want to do anymore, and ramping up the projects that I really like to work on. And two of my favorite projects are building new electrical gadgets and testing things.

In the beginning

This is full circle back to my early engineering days in the ’70s when I was doing industrial power and robotics design in a large packaging plant, and the ’80s when I was building and testing components for nuclear missile guidance systems.

At first blush neither of those jobs seem related to the RV industry and electrical safety, but they actually are exactly on point. For starters, campgrounds have electrical distribution systems on the same scale as an industrial building, with many similar issues.

Packaging Robotics

My first real job involved designing relay controls and mechanical systems for packing glassware on conveyor lines. And part of my job back then was training the plant electricians about electrical safety and best practices.

That’s also when I was formally schooled by the then-new Occupational Safety and Health Administration agency (OSHA) on topics such as PPE (Personal Protective Equipment), Arc Flash dangers, and regular testing of safety equipment such as eye wash stations, lock-out/tag-out, etc… I also learned a lot of shortcuts that electricians would sometimes try to take which could be dangerous. Sound familiar?

Going Nuclear

On the other hand, RV electrical systems have some of the same issues as the nuclear guidance systems I built and calibrated in the ’80s, where voltage calibration is critical to operation, poor connections can lead to product failure (as in missiles blowing up mid-launch), and learning how to measure things down to 6-decimal accuracy helps explain what’s going on under the hood.

Designing my own testing systems

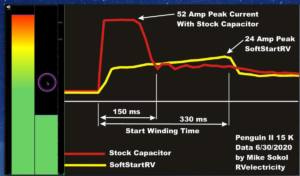

You’ve probably already read about HRDL (High Rate Data Logger) – rhymes with “turtle” – which I designed and built two years ago out of extra parts laying around in my shop. With a few tricks I learned in the ’80 from calibrating the Digital to Analog converters on missile guidance systems, I can now see exactly how various electrical devices in an RV work and interact with other components, logging this highly accurate data hundreds of thousands of times a second and displaying it in easy-to-understand graphs.

This level of data gathering was nearly impossible 40 years ago when I was doing it for military components, and even now would cost around $10,000 in test gear. But I built HRDL for a few hundred dollars worth of spare parts I already had laying around and a week or so of prototype time in my small lab.

In retrospect…

I do feel pretty good that the jobs I worked on the ’80s such as a way to launch nuclear bombs, which could have destroyed the earth, I can now use in my peacetime efforts to help build things like better RV battery management systems, or learn how to start an RV air conditioner more easily, or evaluate Hughes voltage boosting transformers for National Electrical Code compliance.

So when I say I’ve tested something, you can rest assured that I’ve done this to the current state of the art, and perhaps a little better. Some of the RV manufacturers are now beginning to ask for my suggestions on electrical designs, which is great. And I’m currently looking for a grant that would allow me to begin teaching campground maintenance staff better ways to safely test, maintain and repair campground pedestals and power distribution.

Standing by…

So Please Stand By for even more RV electrical information this year and in 2024. I’m just getting started….

Let’s play safe out there… Mike

I do so appreciate your presentations.. thank you

That's awesome. I am doing my own testing - lithium batteries. One is on test now with a $49 load tester, 30 amp cables and a 100 amp hr ReLion battery. One of three I have installed in my RV. The first one produced 90 amp hrs before the voltage dropped to 11.5v DC, my test cuts-off point.Two more to go and testing takes 10-12 hours!!