What is an SCD (Self Contained Device) Outlet?

And why do they seem to fail randomly?

Everyone,

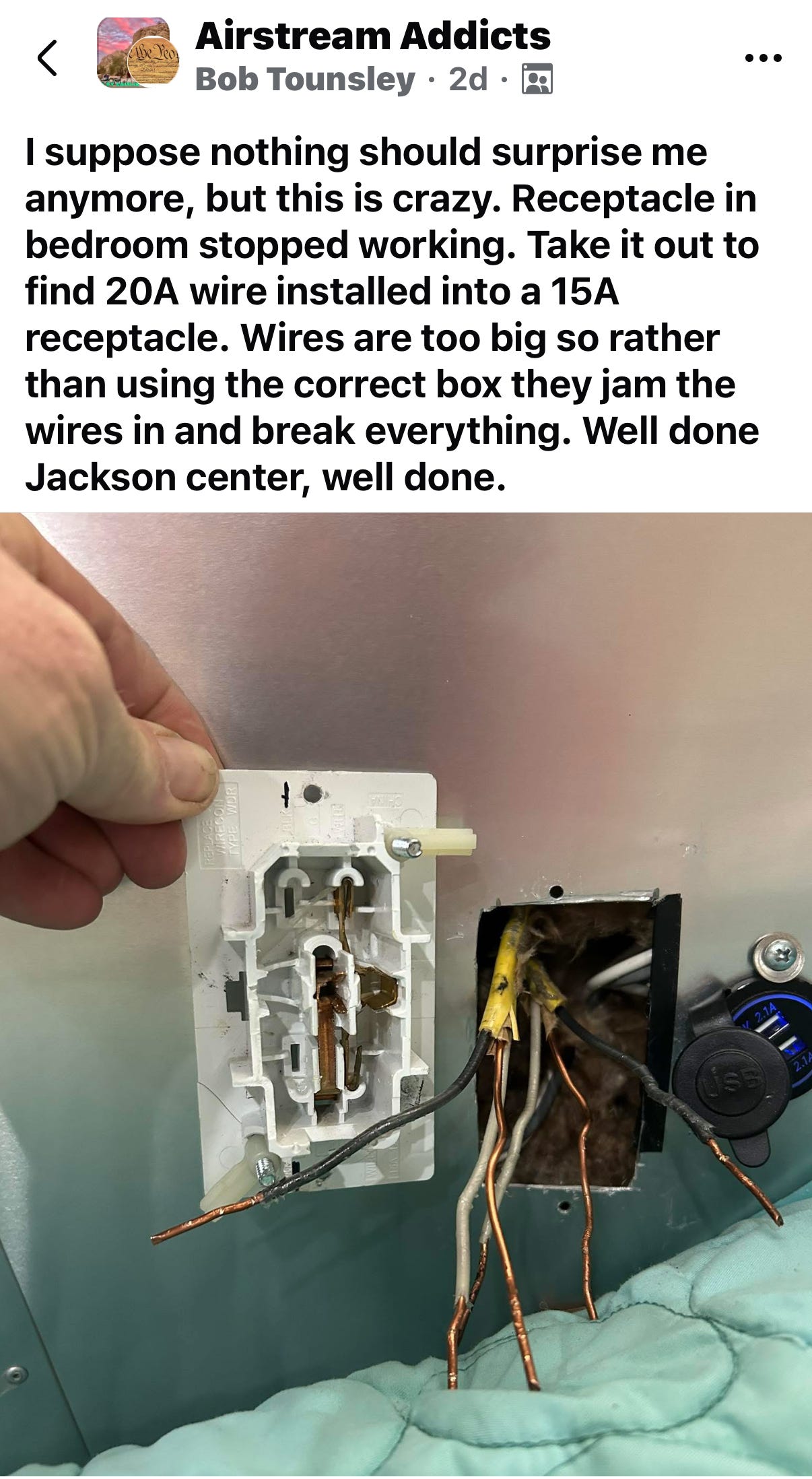

I found this post last week about SCD (Self Contained Device) outlet failure on the Airstream Addicts group. So what exactly is an SCD Outlet and why do they sometimes overheat and melt down under load? Here’s what I know about SCD’s so far, and an educated guess on why they fail.

What are these things called?

These are called Self Contained Devices (SCD) because they don’t require an electrical box for mounting. The RV industry uses them because they are UL listed and much quicker to install than a standard outlet, as long as you have the correct terminating tool and are properly trained. But the Wirecon WT900M terminating tool costs $700, and I’m not sure how much training actually happens.

$700 for a SCD installation tool - Are you kidding?

It sure does cost $700. And this tool requires maintenance as the crimping parts begin to wear. So just how many RV repair shops spend that kind of money on the right tool to do the job? I’m guessing not a lot of them.

Is there a cheaper SCD terminating tool?

Snap-On makes an SCD terminating tool that seats one conductor at a time. But Snap-On warns you in the user manual that they’re very easy to break if used improperly and the company will not honor the warranty if you do break it.

How do most repair shops replace SCD outlets?

While I don’t know for sure, I have seen a few RV technicians seating the wires in the SCD outlet with a flat bladed screwdriver. If done very carefully that might work. But I would not trust a screwdriver/seating installation for high amperage loads in your RV such as electric water heaters, space heaters, and electric fireplaces.

Is there an upgrade/replacement?

Maybe… But it’s a bit tricky since there may not be enough extra wire length and room in the RV wall to install a shallow box and a commercial grade outlet with screw terminations. But I’ve heard of a few clever RV owners who did an outlet upgrade with one of these boxes.

Testing for failure

I’m completely swamped with test work for the next several months, but once things in my FunkWorks Lab calm down a bit I’ll do a high-amperage meltdown test on a few SCD Outlets using my K490 10kW load bank. I’ll report back what I’ve discovered later this fall.

Let’s play safe out there… Mike

After reading this article, thanking Mike for his work in this industry, I have some experience to offer as answers to this subject. I recently retired as an electrical contractor in NJ and I have a bunch of manufacturing experience as well as some time spent in the R&D side of Airport Design for the FAA. Please, don't be impressed... Mike is the man. But, what I will say is that when a manufacturer designs and offers a product and gets a UL listing, they also provide an instruction instruction to keep the UL listing and for liability reasons. The tool and training helps shield them from liability. When the product gets to the installation part, the user assumes the responsibility for the install. Sadly, some business owners care about the money then the customer. And then there's the pressure to go with the flow to stay competitive. I have taken these outlets apart and was struck with fear. I grew to hate Scotch Locs and as an electrician, learned to wrap wire around the switch and outlet termination screws as fast as "stabing" the back of an outlet because I have seen the failure of that practice. Side note... modern outlets won't allow #12 wire to be stabed in the back of devices anymore... the NEC made that ruling. So, we need to simply fix our own campers and help others to do the same. We need to share product information and procedures with each other. The outlet box pictured in Mike's article is available almost everywhere. We need to get to know about Wago's for connections and do the work like it will be inspected. Wire nuts are not intended for high vibration caused by traveling down the road so keep that in mind.

Mike, I have replaced all my SCDs in my RV. I did not need the thin boxes, but did have to enlarge all the openings to fit a clamping box. I had no issue with wire lengths. And I use Wagos, because they are way easier on my fingers.

I did this after having an issue with the fridge, when I opened the outlet up I saw three wires with insulation in the stab-back. I have photos and happy to share. https://www.irv2.com/forums/attachment.php?attachmentid=429199&d=1728439416

The manufacturer allows three but only when insulation is stripped. The neutral wire was barely making contact. After seeing this crap, I opened every outlet. Every single SCD had a deficiency, most dealing with the strain relief. While I was replacing outlets, I changed the 14AWG stranded cord to the slide with 12 AWG cord.