RPBG outlet dangers in EC&M magazine: Part 2

Here's two real-world examples of the damages caused by RPBG outlet miswiring

Dear Readers

Here’s Part 2 of my introduction of the Reverse Polarity Bootleg Ground concept in Electrical Contractor and Maintenance Magazine 10 years ago. Read Part 1 HERE.

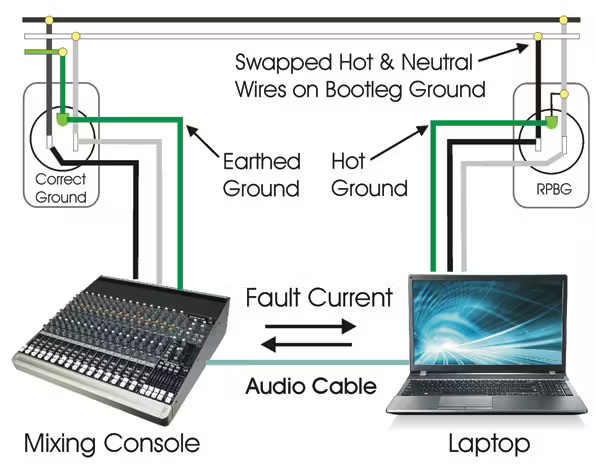

SIDEBAR 1: Interconnected Outlet Fault Currents

While the shock hazard created by a reverse polarity bootleg ground (RPBG) outlet is bad enough, if multiple appliances or gear are plugged into separate electrical outlets — one of which is wired incorrectly as a RPBG — then any signal or control cable between the appliances will be subject to short circuit fault currents between the correctly wired outlet’s ground and the RPBG outlet’s ground, which is actually connected to the incoming hot wire. Because these signal cables are typically small diameter (22 gauge), they don’t offer a low enough impedance to created sufficient fault current that will trip a 15A or 20A circuit breaker. The interconnecting gear often becomes the “fuse” heating up red hot before a wire or circuit board trace melts and opens the ground fault path.

It’s important to note that this equipment failure does not remove the electrocution hazard, given the fact that a technician handling the gear will be still be touching a chassis that is directly connected to the incoming 120V line.

SIDEBAR 2: Home Studio Horror Story

By Adam Olson, Studio Prime

About 10 years ago, I moved to a house five minutes from downtown Denver and decided to turn the upstairs into a recording studio. The house was more than 100 years old with 2-prong (ungrounded) electrical outlets. I was planning on replacing these old outlets with new grounded outlets myself, but in the end, felt it was best to have a licensed electrician do the work.

The electrician I hired came in and rewired the house/studio. However, instead of running new conductors back to the service panel (difficult and expensive in a house of this age) or using GFCI outlets with floated grounds, he simply installed a bootleg ground on the ungrounded boxes using “grounded” outlets. After he tied the ground screw to the neutral wire on the new 3-prong outlets and checked them with a 3-light tester, he said everything was ready to go.

However, over the course of the next month or so, a series of strange events began to occur. The first event happened after I purchased a refurbished computer printer for a couple hundred dollars. The printer was placed in the kitchen and used the same electrical outlet as the refrigerator. I connected a long USB cable from the studio computer to the printer just out of convenience. However, when I plugged in the USB cable, I saw sparks where it plugged into the printer. Assuming there was something wrong with the printer, I returned it to the store for a warranty replacement.

A few weeks later a computer audio interface died after connecting it to a laptop computer. Because this particular model had a history of Firewire failures, it was fixed under warranty. Again, I assumed the Digi box was a problem rather than the electrical outlet, since everything else seemed to be working correctly.

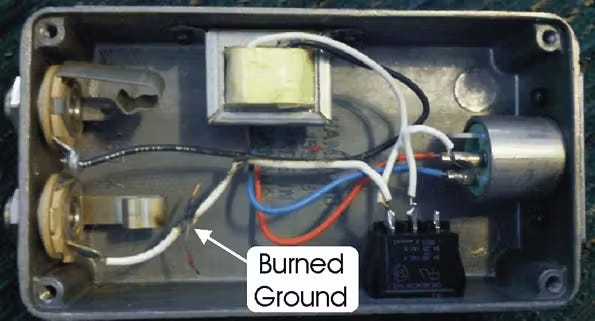

Weeks passed, and other similar mysterious events happened as I interconnected signal wires between various pieces of audio gear (Figure). But the big incident that sent me into full-scale investigation occurred when I connected an audio cable from my new laptop to my audio mixing console, which was powered by a different wall outlet. Once again, sparks flew, and smoke poured out of my new $2,000 laptop!

I used a DMM on each of the outlets, and they tested as expected. Clearly, there was an issue between the outlets. So I ran an extension cord and checked the voltages between the outlets. The results surprised me. I was reading 120V between the grounds of the two different outlets. Flabbergasted, I went and purchased a 3-light tester, which showed all outlets were wired correctly. But after reading the packaging carefully, I found that it stated that the 3-light tester wouldn’t indicate failure if both the neutral and ground contacts were “hot.”

My father is a licensed appliance repairman, and he guided me through documentation and proper steps for reimbursement for damage. As expected, when the electrician returned, he denied that it could have been anything he did, and informed me that he had tested the outlets properly with a 3-light outlet tester. However, after he saw the tests I ran — coupled with the warning on the packaging that stated 3-light testers don’t work for this type of wiring arrangement — he wasn’t too happy. At this point, I proposed that he rewire the outlets correctly and reimburse me for the damages. His first response was that he wasn’t going to do anymore wiring in my place at all. However, after going outside to call his boss, he returned about 20 minutes later and started to work again. This time, he ran a new dedicated 20A circuit to a new outlet, drilling a hole through the wall and brick to boot!

After much paperwork and time, all reimbursements were made, and my studio was back up and running. The final cost to the electrician was more than $6,000, which included reimbursement of my wrecked and damaged sound gear and computer.

Wow, that was a deep dive!

And now you know why I’m so adamant about correct wiring in campgrounds and RVs. The National Electrical Code is there to keep us all safe, so never take shortcuts with electrical wiring. The life you save could be your own.

Excellent review with graphic depiction of a seemingly innocent miss-wire. Question is is their any code to specifically prevent this type of error. Code for 2-wire to 3-wire conversion.