RPBG outlet dangers in EC&M magazine: Part 1

I originally published this article in Electrical Construction & Maintenance Magazine back on July 15, 2013…

Failures in Outlet Testing Exposed

Take a really deep dive into my study on Reverse Polarity Bootleg Grounds

Originally Published in EC&M Magazine - July 15, 2013

Why standard outlet testing methods fail to reveal reverse polarity bootleg ground miswiring situations….

I’ve been a pro-sound engineer for 50+ years and a musician for 60+ years. During that time, I’ve witnessed hundreds of shock events on performance stages, recording studios, and even factory floors. A survey we ran last year on ProSoundWeb.com revealed 70% of the 3,000 musicians who responded had been shocked at least once on stage — some so severely that they were knocked unconscious. I’ve also witnessed dozens of ground-fault current events where signal cables interconnecting sound gear plugged into different electrical outlets mysteriously arced, sometimes turning red hot and melting before my eyes.

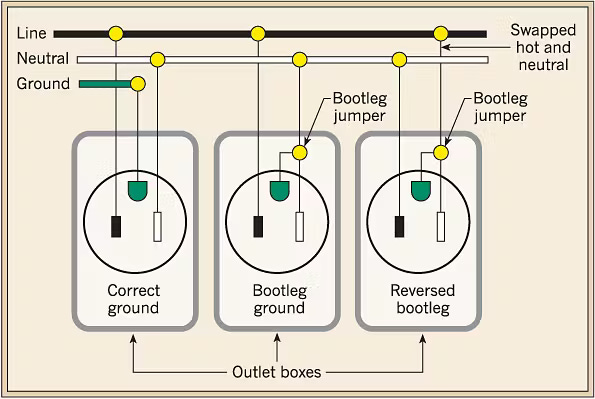

The cause behind most of these guitar-to-microphone shocks appears to be incorrectly wired electrical outlet grounds or damaged extension cords. But while a broken-off ground pin on a power cord is the obvious culprit in most home or stage shock situations, many power outlets show they’re wired correctly when checked with a 3-light outlet tester or even a voltmeter reading between H-N, H-G, and N-G, yet still present a shock hazard. Standard outlet testing methods fail to reveal one of the most dangerous miswiring situations possible, which I refer to as the “reverse polarity bootleg ground” (RPBG), as seen in the graphic below.

As the illustration shows, a bootleg ground (or false ground) occurs when an ungrounded electrical outlet in an older building or stage has been improperly upgraded to a modern NEMA 5-15 or 5-20 grounded outlet. Because office building, sound stage, and home wiring installed before 1965 didn’t require a safety ground, there’s no easy way to install a grounded NEMA 5-15 outlet. Per Sec. 250.130(C) of the 2011 NEC, in that situation, a GFCI outlet should be installed with the ground wire unattached.

Code Alert!

Under what condition can a 2-wire receptacle be replaced with a 3-wire receptacle when no ground is available in the box? Where no equipment bonding means exists in the outlet box, nongrounding-type receptacles can be replaced with [406.3(D)(3)]:

Another nongrounding-type receptacle.

A GFCI grounding-type receptacle marked “No Equipment Ground.”

A grounding-type receptacle, if GFCI protected and marked “GFCI Protected” and “No Equipment Ground.”

Note: GFCI protection functions properly on a 2-wire circuit without an equipment grounding (bonding) conductor because the equipment grounding (bonding) conductor serves no role in the operation of the GFCI-protection device.

CAUTION: Permission to replace nongrounding-type receptacles with GFCI-protected grounding-type receptacles doesn’t apply to new receptacle outlets that extend from an existing ungrounded outlet box. Once you add a receptacle outlet (branch circuit extension), the receptacle must be of the grounding (bonding) type and must have its grounding terminal grounded (bonded) to an effective ground-fault current path in accordance with 250.130(C). However, the Code states this outlet must be clearly marked on front as being ungrounded. Because GFCI breakers don’t need a ground wire to function properly, this type of outlet isn’t a shock hazard. Even if the chassis of an appliance becomes electrically energized due to a high-pot failure, for example, anyone touching the appliance and ground simultaneously would exceed the 4mA to 6mA GFCI trip threshold and be protected from electrocution.”

Why do bootleg grounds happen if they’re a code violation?

Some electricians and DIYers take shortcuts when replacing receptacles in older residences and stages by installing a grounded NEMA 5-15 outlet and strapping the ground screw to the neutral screw on back of the outlet, creating a classic bootleg ground situation. Although this practice is a Code violation, it occurs more often than you think. And because many electrical inspectors rely on a simple 3-light “cube” tester to verify correct wiring connections at outlets, any RPBG outlets can go undetected.

Testing with a 3-light tester

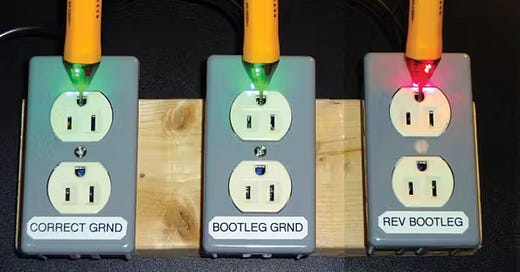

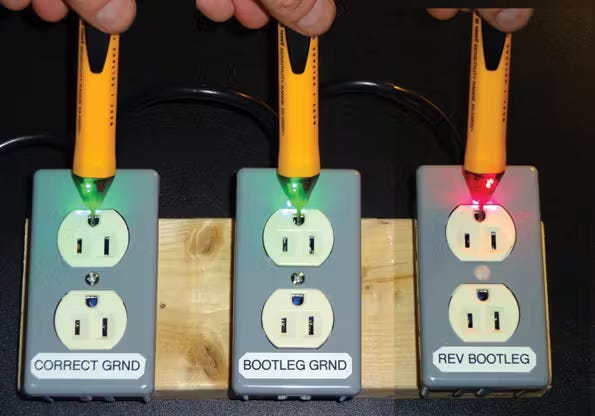

An RPBG outlet will test as correctly wired using any 3-light tester (Photo 1), because there’s no reference to actual earth potential. What makes an RPBG outlet so dangerous is that any appliance (refrigerator), sound gear (guitar amplifier), or even an RV or boat plugged into an RPBG appears to operate normally. But the chassis of the “grounded” appliance is now directly connected to the “hot” wire in the outlet with a low-impedance current path, and anyone touching the body of the appliance will be electrically biased to a full 120V.

That situation itself is not dangerous due to the “pigeon on the power line effect.” But if a person touches the door handle on the refrigerator, strings of the guitar, or metal door of the RV plugged into an RPBG outlet while also touching anything that’s correctly earth grounded, they will receive a potentially deadly shock (around 100mA of current at 120V). Just 10mA of current through your body will result in a painful shock, and 100mA of current for a few seconds is probably lethal if not immediately treated by a defibrillator.

Note that these potential shock currents flow through the ground contact of the outlet, and avoid the neutral and hot contact current paths. So any GFCI outlet wired on a branch circuit extension downstream of an RPBG outlet will probably not sense unbalanced H-N currents and thus won’t trip as designed. In fact, because the GFCI can’t disconnect its own ground contact from the now electrified ground wire, even if it trips, there will still be the full branch current available for the ground fault path up to the circuit breaker trip current (typically more than 20A).

Testing with a voltmeter

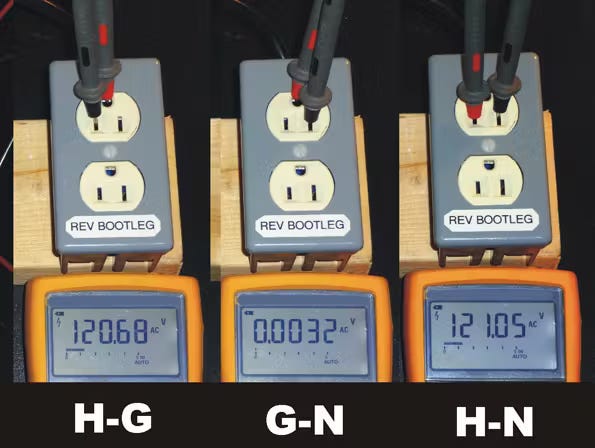

Don’t think a voltmeter is any smarter than a 3-light cube tester. If you simply measure from H-G, G-N, and H-N using any analog or digital voltmeter, you’ll find an RPBG outlet will appear normal (Photo 2). The only hint there’s a bootleg ground is that the G-N reading will be very close to 0V, while in a loaded branch circuit with correctly isolated G-N outlets, you’ll likely see at least 1/2 to a few volts difference between ground and neutral due to voltage drops in the neutral bus.

Testing with an impedance tester

Now that we know a 3-light tester and a voltmeter can’t identify RPBG outlets, what other device can we try? A ground loop impedance tester, perhaps? Although it can properly identify a bootleg ground due to the G-N impedance being too low, it cannot identify an RPBG either. Watch my proof of concept video HERE.

In Photo 3, the ground impedance tester is indicating a (F)alse bootleg ground, but the device can’t tell if the outlet has correct polarity or reverse polarity. It only indicates the false ground with a flashing (F) because the ground-to-neutral impedance is too low. But if an RPBG outlet is feeding an extension outlet on that same branch circuit, the extra resistance of the added wire length would fool the ground impedance tester, indicating 100% Code compliance. Even a visual inspection of a “properly wired” extension outlet fed from an RPGB outlet probably wouldn’t turn up any obvious problems. Note that its neutral and ground connections are both at 120V with respect to earth potential.

A testing solution that works

The gold standard method to identify this sort of miswired outlet device is to use a voltmeter connected to a known good earth ground to test each hot, neutral, and ground conductor in all outlets. But in reality, this type of test isn’t done except perhaps as part of a post-accident forensics investigation.

However, a simple test you can use is to check the outlet with a mid-voltage non-contact capacitive voltage tester (90V to 1,000V range), commonly referred to as an non-contact voltage tester (NCVT) When this tester is used on a properly wired outlet, you’ll hear a beep or see a light only when its tip is inserted in the “hot slot” of an outlet. However, when this type of tester gets anywhere near the front or ground contact of an RPBG miswired outlet, it typically beeps/lights from inches away, because the internal ground strap in the outlet will be biased to 120V, which provides a large electrified surface area.

The green light on the left and center outlets indicates no or low-voltage (under 40V), while the red light on the right outlet indicates a hot ground condition (typically more than 40V for most standard sensitivity NCVTs). Although using a DMM to test between a known earth ground to each outlet contact is the gold standard, adding this NCVT check for RPBG outlets to your test procedure could save lives and dollars.

Wow, that was a deep dive!

And now you know why I’m so adamant about correct wiring at campgrounds and in RVs. The National Electrical Code is there to keep us all safe, so never take shortcuts with electrical wiring. The life you save could be your own.

Stay tuned for Part 2 next week!

Let’s play safe out there…. Mike

Great article Mike, but yards and yards over my head. It's hard for me to keep up with some of your technical articles.

But here's a question. With all the wireless technology that keeps creeping into our everyday lives, how does this affect today;s sound stages? More and more musicians use wireless mikes, guitars, and whatever else can be wirelessly connected. Has this reduced some of their shocking experiences?