Possible Problems With Lithium Battery Upgrades (Rerun March 2023)

It's not as simple as swapping in a Lithium Battery. What to do first!

Dear Readers,

I’m doing something a little bit different in this column. I’m going to introduce one of my colleagues to you, specifically Dennis Wieske from Progressive Dynamics, Inc. For the last year Dennis and I have been discussing how battery chargers and converters in general work with Lithium batteries.

Since Lithium battery conversions are a hot topic nowadays, Dennis did a YouTube Livestream with me which I’ll repost later. And I want you to meet him through a basic article he just wrote about the potential problems of upgrading to a Lithium battery in your RV if your charging system wasn’t designed to handle it.

Take it away, Dennis Wieske…

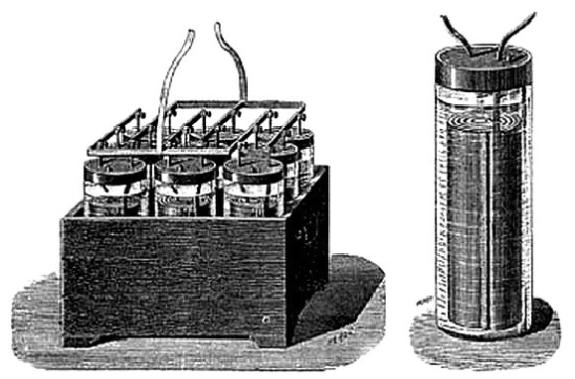

It’s the newest trend, replacing that old, messy Lead Acid battery in your RV with a new Lithium battery. Just swap it out with your old battery and away you go. No more checking the water level, no more cleaning corrosion from the battery posts. It will charge faster, provide more usable power and last longer than that old wet cell. Most of this is true, but it’s not that simple. This article is about the Lithium Iron Phosphate (LiFePO4) battery and what you may need to know to make an informed decision to upgrade your RV to lithium power.

Are they new technology?

Lithium batteries have been on the market for some 30 years. We have all heard the horror stories of phones, laptops and other Lithium-powered devices catching on fire and creating very dangerous situations. However, the LiFePO4 or LFP battery by composition is not subject to thermal runaway as are other Lithium types. It does not release hydrogen gas as a Lead Acid (LA) will. The LFP battery is by far a much safer power source.

Can I build my own battery?

Unless you are very knowledgeable with Lithium technology, I do not recommend building a battery from miscellaneous parts available on line. Instead, purchase a complete battery package – preferably UL approved. These units contain a smart Battery Management System (BMS). The BMS is the brain of the battery controlling the many aspects of charging and discharging of the cells in a battery pack. The unique characteristics of the LFP cell make an ideal replacement for the standard 12-volt automobile battery.

Positives + + +

On the plus side, LFP batteries are lighter, can be discharged 100% and will charge much faster than the Lead Acid battery.

They also have a relatively constant output voltage over most of the discharge cycle.

Many LFP batteries are rated for 3,000 to 5,000 recharge cycles versus 200 to 500 recharge cycles of a LA battery – so up to 10 times the life of a Lead Acid battery.

You do not need to connect to a trickle charger while in storage like any Lead Acid or Absorbent Glass Mat (AGM) battery requires. In fact, many manufacturers recommend discharging your battery to 50% while in storage.

You can also see a significant cost savings over the life of the battery.

With the help of recycling, we may also benefit our environment compared to Lead Acid batteries.

Negatives - - -

On the negative side; These batteries are expensive. But while your initial cost is very high, over the life of the battery the cost is actually much lower.

Most LFP batteries will only provide a discharge rate of two times the rated power of the battery. This may affect the ability to start your on-board generator or power a large inverter to run your air conditioner. In some cases, a super-capacitor is added to provide extra peak current for these situations.

Charging at temperatures below 32 F will damage the cells. Some manufacturers are beginning to incorporate methods to protect the cells during lower charging temperatures. The battery will shut off when it reaches 0% of charge. You won’t get a warning unless to have a smart battery monitor.

LFP batteries require a higher charging voltage (14.0 to 14.6 volts DC) than a standard LA battery charger. So using a charger for an AGM or Lead Acid battery may not allow your Lithium battery to be fully charged.

Plus, you may need to upgrade other aspects of your RV’s 12-volt charging system. For example, your charger must be capable of providing a continuous output at the recommended voltage for an extended period of time. That means that the wire between the charger and the battery must be of sufficient gauge to handle the extra current and have minimal losses at full power. I would recommend no more than a 2% voltage loss end to end. This includes the charger and battery negative connections to chassis ground.

You’ll also want to replace the Shortstop circuit breaker with a manual resettable circuit breaker (Bussmann CB 185 series or equivalent) with a rating of 120% of the charger or load current, whichever is higher. Note the Shortstop breaker in your RV is usually rated lower than the original charger. It won’t take long before it burns out.

Any portable generator must be capable of handling the full rated power of the charger plus any additional 120 VAC appliances that will be running simultaneously. The maximum recommended load should be no more than 80% of the generator rating.

It would help to have a battery monitor calibrated for Lithium battery voltages; this will allow you to monitor your state of charge (SOC) to determine if a generator run is warranted.

Some converter/charging manufacturers may have a Lithium charging option available for charging at 14.6 volts, but it may mean replacing your original unit.

Progressive Dynamics offers many Lithium options in the current product line. Each of the “ALL IN ONE” power centers offers an option to change from the default Lead Acid setting to Lithium. Each has a converter replacement section for Lithium charging, as well – a requirement for older models.

There is also a line of deck mount Lithium chargers. Many older units have an option for manual control of the multi-stage “Charge Wizard.” Manual selection of the BOOST mode will provide 4 hours of rapid charging at 14.4 VDC. Progressive Dynamics is committed to providing quality Lithium converter/charging systems.

Final thoughts…

I hope this provides a clear understanding of the requirements and considerations when upgrading to a LiFePO4 battery. You will have many years of satisfying use when you take the time to do the homework first. Don’t forget there are also Solar Lithium options and DC to DC Lithium converters to charge from your engine alternator.

Disclaimer:

Dennis is a Senior Service Technician working in the Service Department at Progressive Dynamics, Inc. His responsibilities include failure analysis of returned products, product evaluation in conjunction with customer usage, customer support via telephone, and email providing troubleshooting help and replacement/upgrade recommendations.

Hey, it’s me again…

Let’s all thank Dennis for his contribution to our knowledge base. Later this week I’ll post a link to my hour-long Ask-the-Expert interview with Dennis. He’s a walking rolodex about which chargers work with different battery technologies.

I am at the point where I need to replace the 5 year old 6v AGM batteries on my TT so this article was timely. Thanks (again) for the useful information. As someone who got into RV life seven years ago with little knowledge of AC/DC electrical systems you’ve been a consistent source of trusted information and I’ve really enjoyed learning from you.

As Mike has pointed out so well, LFP batteries are hardly "plug and play" or a "drop-in replacement" as many mfrs and vendors claim.

Mike pointed out all of the most important considerations, but a couple others are:

1) Terminals and connections. The terminals on most LFP batteries I've seen -- including the 2 Lion batteries we have -- are ridiculously undersized. 6mm or 8mm threaded inserts are common. Not only are they small, but it is a weak design because the torque placed on the hardware can break the insert loose. They are not meant to accept large cable with 5/16 or 3/8" ring terminals.

The only decent design I've seen are the 'blade' terminals on Battle Born batteries.

We ended up using the posts Lion included that are similar to the posts on ordinary lead-acid batteries. I bought some nice mil-spec battery post terminals The problem was that the Lion posts are perfectly cylindrical, while FLA battery posts are sightly conical. That meant that the contact surface was much smaller than it ordinarily is, but it seems adequate. We used the bolt on each terminal to attach the #4/0 welding cable. The Lion posts have threaded holes on top, which we used to secure the 2 cables to connect the batteries in parallel.

Bottom line -- it took a lot of time and it is not very pretty. It does work and there is no discernable heat at any of the connections when charging at 100A+ (50A per battery). They will start the (small) diesel generator (QD 3200) and even run the AC (13,500 BTUI Coleman). We did that inadvertently...

2) This is small in comparison, but the existing battery hold-down hardware will probably not fit. I had to rig up something with angle iron and all-thread.

3) Oh, and charging LFP batteries may be too big a load for the alternator. Without testing, it's best to disconnect the cable from the alternator to the house batteries. If the alternator is used, a DC to DC is needed, at a cost of several hundred dollar. They are generally limited to 30-40A, or 15-20A per battery, which means a long charging time.

Other than that, no problem!