May the torque be with you!

Make sure to check your electrical connections for looseness before spring camping

Dear Mike

I really liked the “Mike’s Gadget” Torque Screwdriver in a previous RVelectricity™ Newsletter, but I can’t find a chart showing proper torque values. Please help!!! —Larry the DIY Guy

Dear Larry the DIY Guy,

I’m so glad you’re taking this problem seriously. I get emails nearly every week from readers who have burned up Automatic Transfer Switches and Shore Power Plugs, and loose screws seem to be a major factor.

One thing to remember is to be sure ALL power is off before touching anything. So unplug from shore power, turn off your generator, and power off your inverter.

Safety First!

So, make sure there’s no possibility of 120-volt power in your RV before checking any AC connections. And if you’re going to re-torque any of your 12-volt DC screws, be sure to disconnect the batteries so you can’t create a short circuit and melt a wrench, or get your wedding ring or metal bracelet trapped in the fault current path.

What are the numbers?

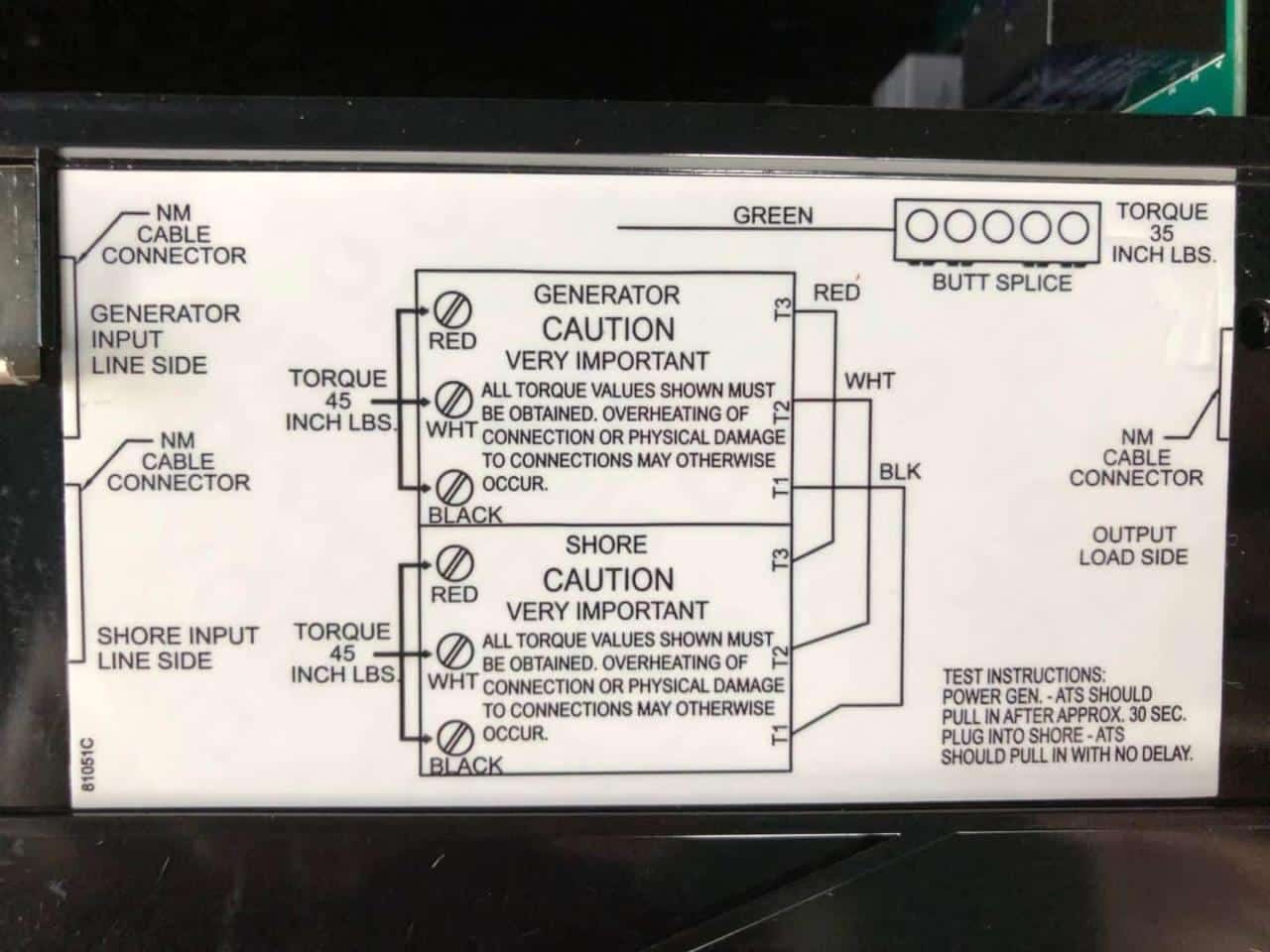

Just remember these numbers are all in inch-lbs of torque, NOT foot-lbs like your wheel lugs. You’ll also want a torque-limiting screwdriver that can be set from 20 in-lbs to 60 in-lbs, and have the proper bits for each type of screw you need to re-torque.

Also, back off each termination screw a little first, and then retighten them until the torque screwdriver clicks. That breaks up any corrosion in the threads that could give you an inaccurate torque value.

You can get a proper torque limiting screwdriver for less than $50 at many gun shops or on Amazon HERE.

Loosen the torque setting when you’re done

After you’ve finished your yearly screw torque maintenance, you’ll want to back off the torque setting on the screwdriver to as low as it will go. This will prevent accuracy drift from the spring being under tension for months at a time.

WFCO Load Centers

Standard Circuit Breakers

Southwire Transfer Switch

That’s a wrap!

OK, everyone. Remember that electricity is a useful and powerful force, so we all need to pay attention to safety precautions while using it.

Let’s play (and torque) safely out there…. Mike

Mike, as usual a very good article. Especially true when stranded wire is used and especially in high vibration, also heating and cooling of the conductors. I have personally seen where someone tightened down on a stranded wire to the point that they severed the strands, effectively reducing the current carrying capacity. Electrical terminals are not designed to be torqued to a 1/4 turn before they are stripped. I also like to use a NO-OX contact grease on most of my electrical connections

Do you recommend spraying the screws with a contact cleaner like deoxit? I had not heard previously about a yearly maintenance cycle for RV load centers. I would also think it is dependent on how much an RV is used. We certainly don’t do this at our homes.